SWIR (Short-Wave Infrared) refers to the light wavelength range of 900nm to 2,500nm. SWIR light behaves similarly to visible light, in that photons are reflected or absorbed by an object, providing the strong contrast needed for high resolution imaging. Like visible light cameras, SWIR cameras deliver high resolution images at high frame rates and offer selectable bit depths of 8, 10, 12, and 14 bits.

SWIR imaging is especially good for:

The following examples highlight some of the application spaces that can be addressed:

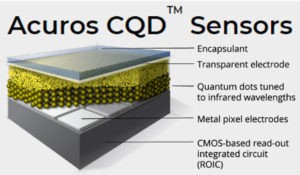

There are many application spaces using SWIR cameras and lighting for the inspection of silicon and gallium arsenide semiconductor wafers and photovoltaic cells. Certain SWIR lighting wavelengths pass through these wafer materials and chemical depositions. SWIR light wavelengths will not pass through metal, so objects such as bumps, circuits, and alignment targets will be visible.

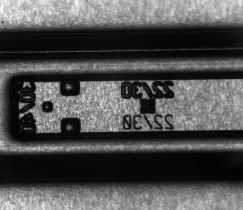

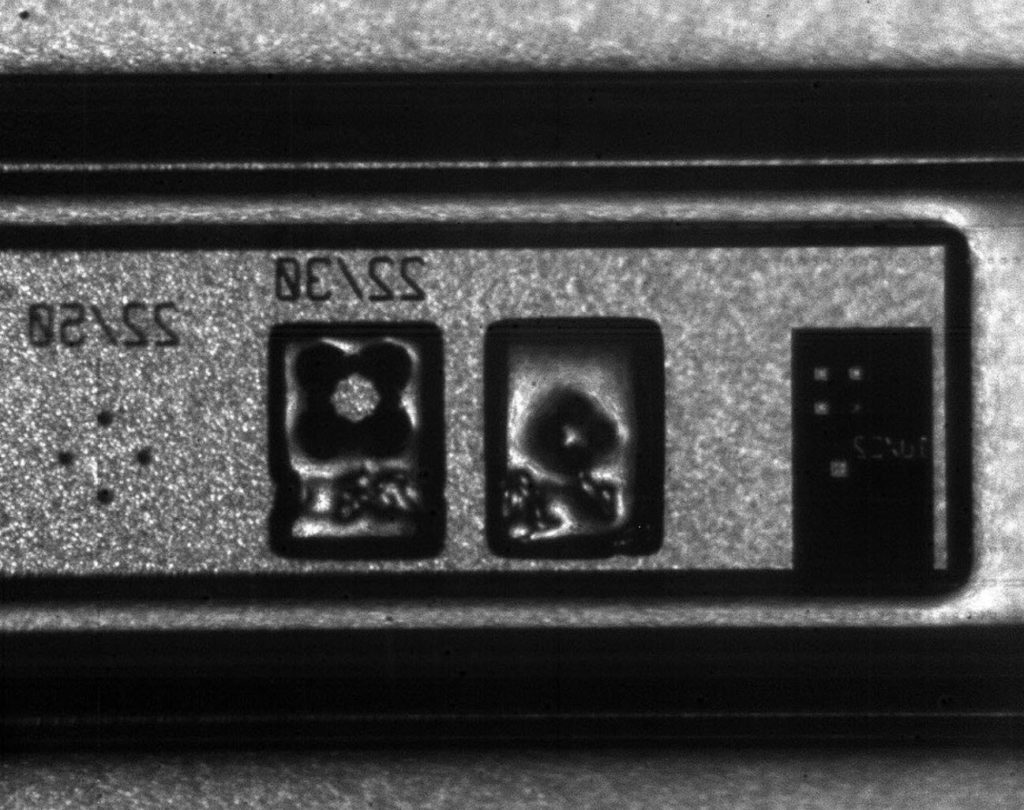

SWIR imaging enables alignment mark and wafer bump inspection on bonded wafers.

Alignment Targets on Bonded Wafer Layers Can be Imaged

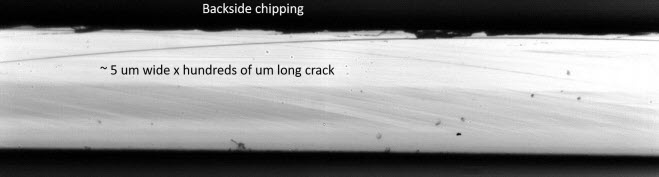

SWIR imaging can be used to detect micro-cracks and chipping near the edge of diced wafers that can’t be seen in visible light images. The cracks interfere with the SWIR light transmission to make these defects visible.

The SWIR Lighting Path is Interrupted by the Crack in the Silicon, Making it Visible

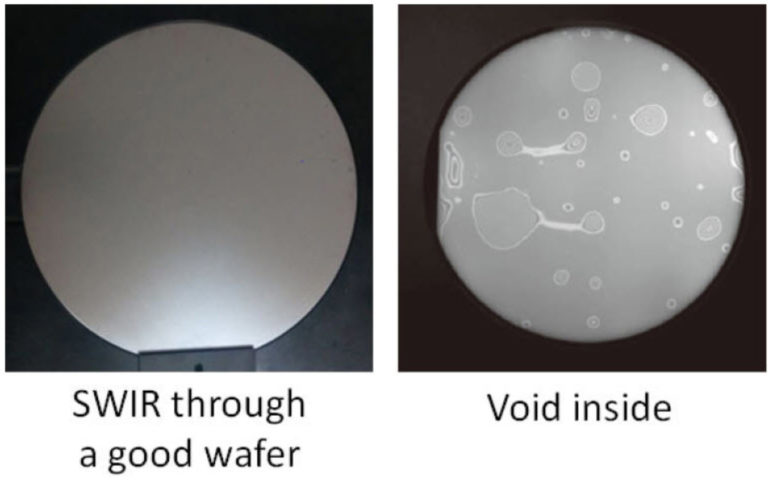

Voids, air pockets, and particles can be detected in the wafers.

Detection of Voids in New Wafers

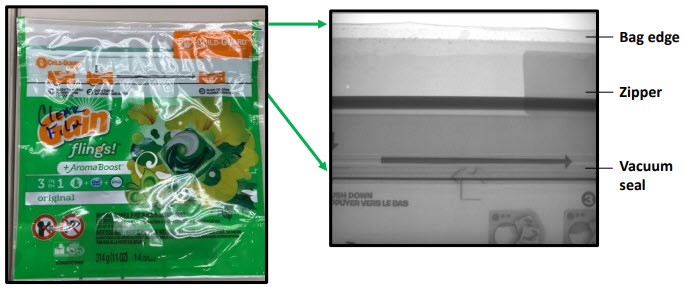

The contents or features within opaque and printed paper and plastic packaging become visible and inspectable when backlit with SWIR lighting.

In the following example, the printed opaque plastic bag is backlit at 1450nm and the bag edge, the zipper, and the vacuum seal areas are visible without interference from the printing on the bag. The bag may then be inspected to ensure none of the contents is stuck in the zipper or in the vacuum seal area, which may lead to leaking or spoilage.

SWIR Lighting Passes Through the Printing, Making it Easier to Inspect Key Features

In the example below, the contents within plastic packaging become visible because the SWIR back and front lighting pass through the printed packaging. This is ideal for food packaging inspection to verify the contents are correctly packaged or are present at all. The same concept may be applied to medical and surgical products packaging.

The Packaging Disappears, Permitting Inspection or the Verification of Presence of the Contents

Liquids typically absorb specific SWIR wavelengths and can appear dark, enabling fill-level verification behind plastic labels or within tinted or opaque vials and bottles.

SWIR Lighting Passes through Labeled Vials and Plastic Packaging to Detect Fill Levels

Since liquids and adhesives absorb specific SWIR wavelengths at varying degrees, based on their chemical composition, additional applications requiring the detection or differentiation of clear liquids or contamination, liquid coating coverage, and clear adhesive presence on surfaces can be addressed.

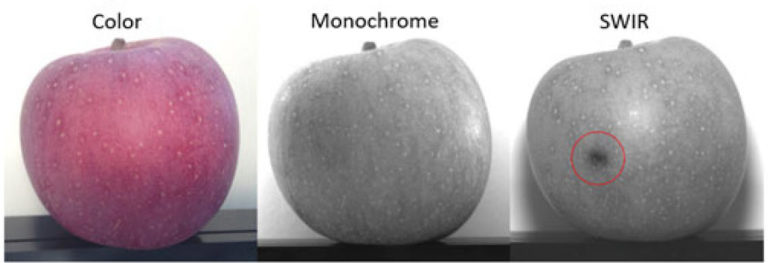

Water absorbs 1,550nm and other SWIR wavelengths, making it appear dark in the acquired image. In produce sorting, bruises, as shown below, appear as dark spots based on the increase in water content at that location.

SWIR Light Highlights Where the Water is Concentrated, Making it Easier to Image Bruising

The ability to detect water or liquid can also determine whether the item is dry or wet, and ready for further processing, such as checking grain moisture content, dyed textile moisture, processed particle board moisture content, and for seal/packaging inspection of high-moisture goods.

Although not a true thermal camera in terms of measuring temperature, SWIR imaging is used to inspect hot glass products, looking for temperature uniformity variations that present themselves as grey value variations in the acquired image. These localized temperature variations often lead to defects in the glass.

SWIR imaging is able to look through the glass to inspect the far “walls” for temperature variations. It’s less costly to “recycle” defective glass products at this point in the manufacturing process than after the glass completely cools.

View of Glass Bottle Imaging with a SWIR Camera, No External Lighting is Required

SWIR imaging can also be used to inspect molten metal. It can help differentiate between the molten metal and the slag, through imaging the differing grey values, because of the variation in temperature between the two. The presence of slag in the molten metal will impact the quality of the subsequent process or the final product.

SWIR Lenses, Standard & Telecentric

Although standard visible wavelength glass lenses can sometimes be deployed with SWIR cameras, SWIR-specific lenses include optical coatings that enhance the focusing capabilities, contrast, and image quality within the SWIR range.

Factory automation lenses for SWIR imaging are available as standard and telecentric lenses in a range of focal lengths, magnifications, and camera mounts from our lens partners at Goyo, Navitar, Opto Engineering, SWIR Vision Systems, VS Technology, and others.

Navitar Resolv4K and Other High-Magnification Lenses are Available with a SWIR Coating

SWIR lighting is available in a variety of form factors and in specific SWIR wavelengths for back lighting or front lighting. Effilux and Smart Vision Lights offer a range of SWIR lighting options.

SWIR Lighting Form Factors

Typical SWIR lighting wavelengths include 1,050, 1,200, 1,300, 1,450, and 1,550nm.

For additional information on SWIR lighting, please visit our SWIR Lighting Page.

To discuss whether SWIR imaging can solve your inspection challenges and to arrange an evaluation of your parts, please contact R.J. Wilson, Inc.