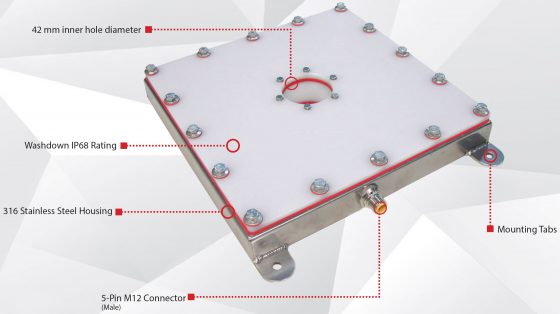

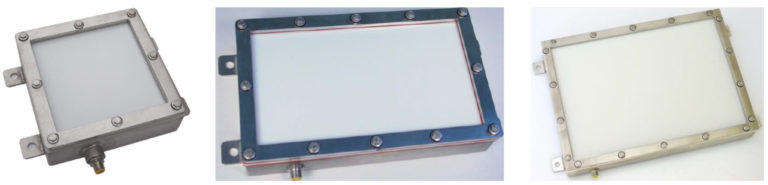

The UltraSeal backlights and newly-introduced bar lights from Advanced Illumination are purpose-built to perform in extreme wash-down environments and feature a rare IP69K rating. From liquid immersion to high-pressure steam to corrosive solutions, the UltraSeal products stand up to the realities of what “wash-down” means – both Cleaning and Disinfection.

The UltraSeal lights feature a patent-pending design that is virtually crevice-free, making them ideal for hygienic inspection environments, aseptic manufacturing and packaging, food and beverage applications and any application where a commitment to wash-down protocols is essential to helping ensure consumer safety.

The UltraSeal concept is being applied to other Advanced Illumination products, so please contact R.J. Wilson, Inc. for additional information and to discuss your wash-down machine vision lighting challenges.

The new LZEW300 300mm Bar Light features a first-of-its-kind FDA-compliant non-stick finish, applied to a 2-pound aluminum housing. This is a cost-effective, lightweight IP68 lighting solution. In addition to a choice of beam angles, the LZEW300 offers single-connector or 2-connector daisy-chain versions to reduce cabling requirements.

A 316 stainless steel housing option is available for a more traditional wash-down enclosure.

The Spectrum Illumination WMRL8.5 is a compact IP68-rated 8.5-inch diameter ring light.

The Spectrum Illumination WMDL7 is a compact IP68-rated 7-inch diameter dome light.

both continuous and strobe operations.

The EFFI-FLEX-IP69K bar lights come standard with an AutoStrobe function that maintains 3X the standard brightness for 2 seconds, and then brings the output to standard brightness. Each time the trigger is detected, the light goes into AutoStrobe for added intensity.

For constant-on use, a standard driver is available.

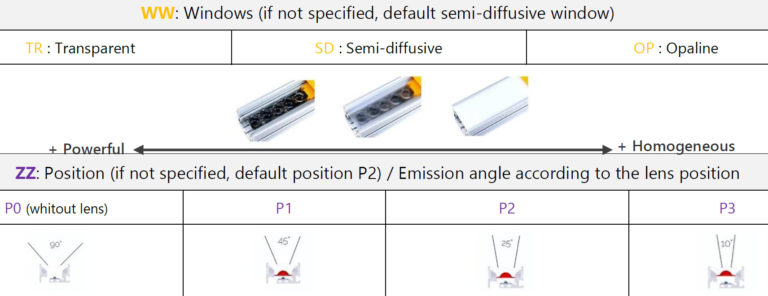

The EFFI-FLEX bar lights can be configured with a choice of front window diffusion levels: Transparent, Semi-Diffuse, and Opaline. The LED beam angle is also factory-set to one of four positions, as shown below.

EFFI-FLEX IP69K lights may be configured for front-lit line scan imaging by including the LS Filter. The optional LS filter sits behind the Transparent Window and projects a tighter line of diffuse light across the field-of-view, as shown. As with any bar light application, there will be intensity fall-off near the ends of the bar light, so additional “overhang” should be included on each end when calculating the required bar light length.

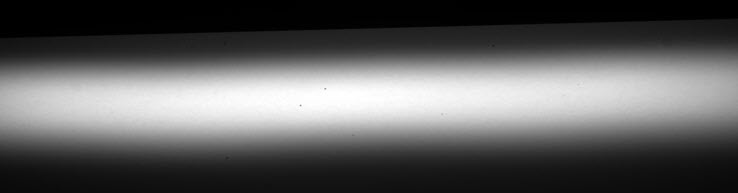

The EFFI-FLEX-BL IP69K Linear Backlight features an opaline window and twice the density of LEDs within the light (compared to the EFFI-FLEX bar light) for a more even and intense background when used with a line scan camera. The backlights have a constant-on driver. The EFFI-FLEX-BL-IP69K backlight is the same physical size as the EFFI-FLEX-IP69K bar light.

Composed of 12 high powerful 405nm UV LEDs.

TPL Vision has introduced an IP69K version of its EBar bar light, with lengths up to 1,250mm. The food-grade compliant stainless-steel frame and smooth cylindrical surface stand up to cleaning solvents and high humidity.

Back Light Version of the IP69K Bar Light Available

IP69K Bar Lights up to 1,250mm in Length

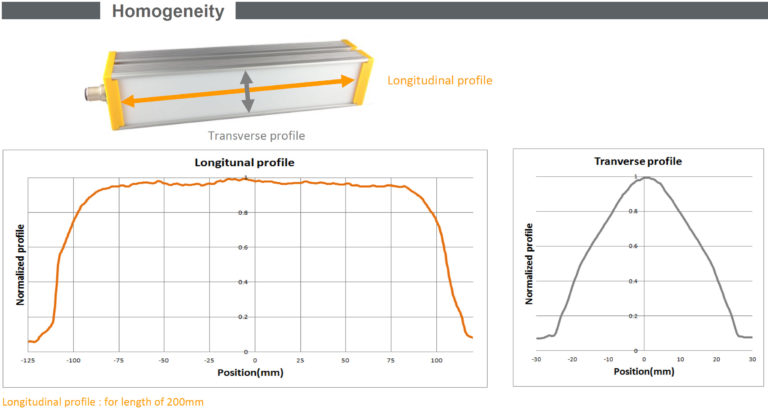

TPL Vision also offers an IP69K back light with a similar form factor to the IP69K bar lights. A diffuser is used to provide wash-down-capable backlighting for line scan use or to provide diffuse front lighting at shorter working distances.

When considering wash-down lighting, keep in mind that a wipe-down cleaning regimen in a clean-room may still use caustic chemicals that can deteriorate a light’s metal or plastic housing, adding to contamination rather than mitigating it. The materials used in the housings for wash-down lighting are specifically designed to mitigate the effects of caustic chemicals used in high-pressure and often in wipe-down methods of cleaning