APG Vision camera enclosures offer multiple levels of protection. Quite often, the main purpose of a camera enclosure is to keep idle hands away from the camera and lens. However, when the camera and lens must be protected from its environment to maintain system uptime, a suitable specialized camera enclosure is required.

APG Vision’s enclosures support cameras from most manufacturers, including Allied Vision, Basler, Cognex, Datalogic, Keyence, Teledyne Dalsa, Vision Components, Zebra, and more.

Enclosures are offered for food and beverage production and packaging, pharmaceuticals, automotive, mining, security, and gas industries. APG Vision also offers custom enclosures and OEM housing solutions. Full-custom and semi-custom enclosures are also available, taking advantage of APG Vision’s decades of stainless-steel and aluminum fabrication experience. APG Vision enclosures are built in the USA.

Which Camera and Lens Will be Used?

The selection of a camera enclosure within a protection category is based on the physical size of the camera and lens configuration. Provide the camera and lens model and the size of each. If the camera mounting pattern doesn’t yet exist as a part number, APG will create a new part number to accommodate the camera’s mounting requirements. Fasteners for the camera are included with the enclosures.

Basic Protection from Tampering

These enclosures are designed to protect the camera from impacts, dust, dirt, splashed water, and idle hands. The light weight of the barrel enclosures makes them ideal for robot-mounted cameras.

· Ratings, Depending on Model: IP52, IP64, IP65, NEMA 12 when equipped with a sealed viewport.

· Materials Used: 6061 aluminum and 304 stainless steel construction.

· Tool-less access to the camera and lens for focus and iris adjustment.

· Air cooling/air curtain option available.

Increased Protection

The 24C, 35C, and 47C Series enclosures are rated NEMA 4 / IP65, guaranteed to be dust proof as well as protecting against low-pressure spray downs. Some models are rated Indoor/Outdoor NEMA 4 / IP68. These enclosures are constructed with anodized 6061 aluminum and fastened with 18-8 stainless steel.

All gaskets are made from a silicone rubber, Viton™ rubber, or EPDM foam. The viewport window may be a clear acrylic, glass, or clear polycarbonate, with a scratch-resistant coating applied to either side. Air cooling/air curtain options are available.

The enclosures are designed so that once the enclosure cover is removed, the user has full access to the camera & lens settings.

Food Grade, Wash-Down, and Corrosive Environments

For added protection and to meet FDA/Food-Grade standards, APG’s S, L7, and L10 Series enclosures are rated NEMA 6 / IP68, guaranteed to be dust tight, as well as protecting against continuous liquid immersion. They are constructed and fastened with Corrosion-Resistant 316 Stainless-Steel. Additional sealing is used to configure IP69K-rated enclosures.

Wash-down enclosures are designed to work in highly corrosive environments and in food applications, with care taken to reduce pockets where water might sit. The enclosures are designed so that once the enclosure cover is removed, the user has full access to the camera & lens, taking the guesswork out of changing focus and f-stop settings.

All gaskets are made from a silicone rubber, Viton™ rubber, or EPDM foam. The viewport window may be a clear acrylic with a scratch-resistant coating applied to either side, or durable glass.

An optional thermostatically controlled heat blanket is available inside the enclosure. Cord grip options include: Single cable cord grips (PG11), drillable (PG29) 29mm cord grip, 1″ NPT conduit, and 1/4″ NPT connectors for air cooling and pressure regulation.

Liquid-Cooled Enclosures

Maintaining operation in a hot environment requires liquid cooling. Designed for high-temperature applications, the CC series is designed for environments with ambient temperatures up to 550˚ Fahrenheit. Another simple, yet effective design of 316 stainless steel, with a Quartz glass viewport. These housings include a drillable cord grip, allowing for use of premade cables.

Explosion and Flame Proof Enclosures

These enclosures are rated for use in explosive gas and high-dust environments for monitoring and inspection.

· Compliance with NEC Class I, Div 1 & 2 Groups B, C & D, Class II, Div 1 & 2 Groups E, F & G, Class III

· UL Listing 886

· CSA Certified – Standard C2 No. 30-M1984

· CENELEC approval

· NEMA 3, 4X, 7 & 9

· Cast aluminum construction

· One or two 3/4″ NPT fittings for cable conduit

Using Pre-Made Cable with an APG Split Cord Grip

You don’t need to disassemble your pre-made camera cables to route them into an APG camera enclosure. A unique split cord grip design permits the use of pre-made cables. Provide the number of cable holes and their diameters and APG will drill the cable holes required to ensure a proper bore and liquid-tight seal when the cord grip is fully assembled.

Additional accessories, such as pan-tilt mounts, are also available.

What Do IP and NEMA Ratings Mean?

The following tables outline the primary IP and NEMA Protection Levels for camera enclosures and what they mean. The rating is typically the first requirement specified and APG Vision enclosures are built to adhere to these ratings.

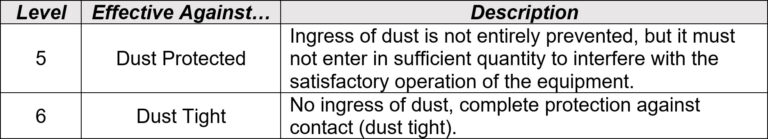

IP means Ingress Protection. The First Digit is for Solid Particle Protection. For camera enclosures, the first digit is typically:

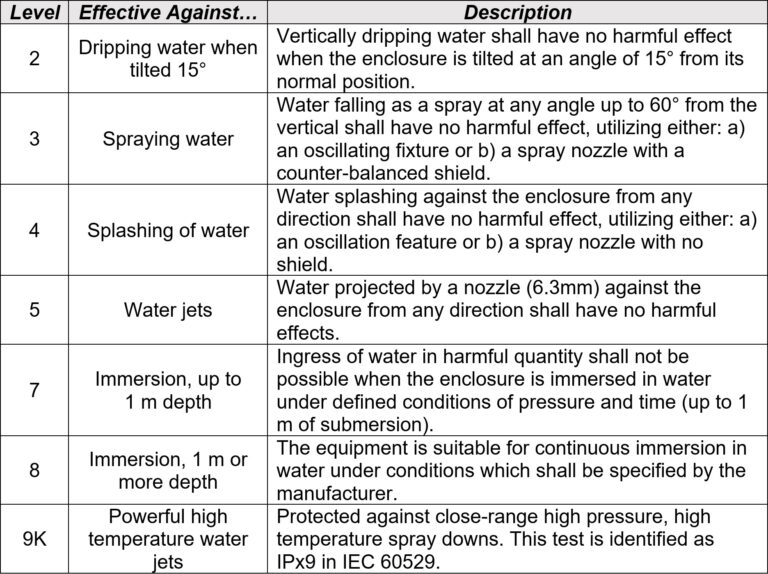

The Second Digit is for Liquid Ingress Protection. For camera enclosures, the second digit is typically:

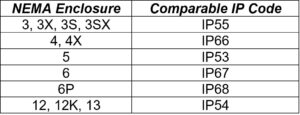

NEMA Ratings and the Comparable IP Rating

Please contact R.J. Wilson, Inc. to discuss your camera enclosure requirements at [email protected] or at 781-335-5500.