Metrix Vibration Monitoring Can Save Rotating and Reciprocating Machinery from Significant Damage.

Metrix leads the industry in vibration monitoring systems for manufacturers and users of

Any problem that results in a rotating or reciprocating piece of equipment

going out-of-balance is going to escalate in cost quickly if the problem persists

Vibration monitoring is made simpler with 4-20mA vibration transmitters, high-temperature velocity sensors, and innovative impact transmitters that interface with the facility’s PLC (Programmable Logic Controller), DCS (Distributed Control System), or SCADA (Supervisory Control and Data Acquisition) system for machine vibration monitoring.

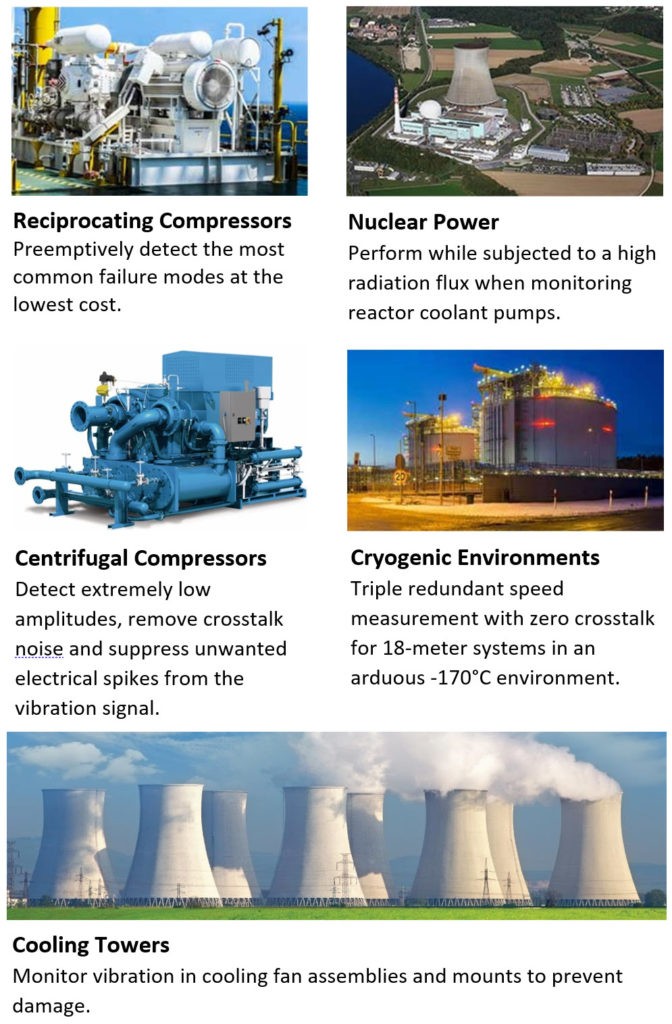

Metrix sensors are available in explosion-proof and underwater housings and for high-temperature applications, such as in gas turbines.

Metrix Velocity, Acceleration, and Impact Sensors, Including Underwater and High-Heat

In addition to vibration sensing of mounts, motors, and housings, Metrix offers a revolutionary proximity sensing transmitter to detect shaft position variations caused by support bearing failure, rod drop, or other shaft support integrity issues.

Metrix Digital Proximity System Transmitter

and Driver

The Metrix Digital Proximity System works with Metrix probes, as well as existing proximity probes and cables from other manufacturers, including Bently Nevada. The Metrix DPS is compatible with 5mm, 8mm, and 11mm proximity probes, with cable length support up to 12 meters and more.

The DPS can be field configured for a variety of common shaft materials, as well as for unknown shaft material, probe type, and cable length. It offers high amplitude and frequency resolution in a revolutionary device.