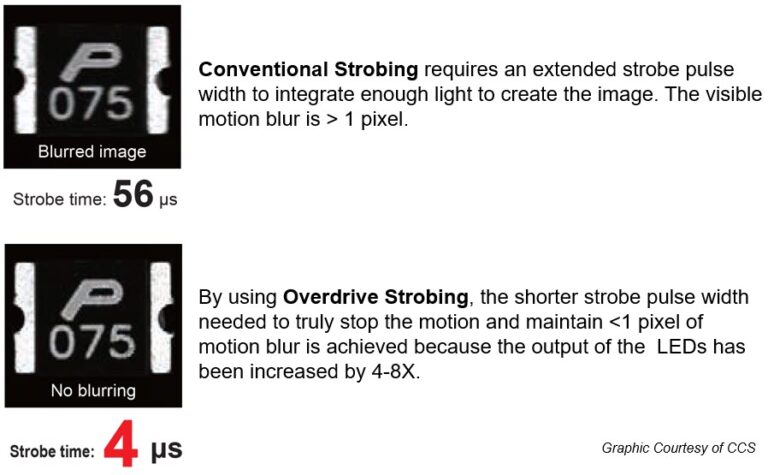

We typically need to strobe the LED lighting when the scene is of a moving object. It is critical to limit the amount of pixel-blur in the captured image to less than 1 pixel. Otherwise, the features we are dependent upon for alignment or inspection may not be properly and consistently presented. Any calibration may become invalid.

The faster the object is moving, the shorter the strobe light pulse needs to be to maintain motion blur below 1 pixel in the captured image.

A simple calculation of the maximum strobe light on-time required to maintain <1 pixel of motion blur is:

While reducing the camera’s exposure time or strobing the light will minimize pixel blur due to motion, we’re also reducing the amount of light available to the camera to create an image. It may become necessary to strobe in an overdrive mode to achieve sufficient light “intensity” to capture a high-quality image.

Sometimes the light intensity required exceeds the ability of the lighting configuration to deliver it. This “light starvation” is often the result of:

With basic strobing, the light’s intensity will not exceed the maximum “always-on” intensity of the light, but the light will “flash” for the specified period, effectively “stopping motion” in the captured image. If a short enough duration strobe pulse can be used to stop the motion and if the light intensity is sufficient to capture the image, basic strobing may be used.

The concept of overdriving LEDs is to send a higher-than-normal current to the LEDs for a shorter period, increasing the light’s intensity by 3X-10X during the shortened strobe output pulse without damaging the LEDs.

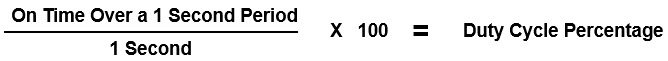

Overdriving the LEDs increases the amount of heat created, so the maximum duty cycle, or percentage of on-time to off-time, will be specified by the manufacturer to maintain a safe operating temperature that won’t damage the LEDs. If the lights reach a dangerous temperature, there are built-in safety functions, on some lights, to shut down or attenuate the intensity so as not to damage the LEDs. This may affect the vision system’s performance and uptime, so all the lighting parameters need to be considered in advance.

When overdriving the LEDs, the maximum duty cycle is typically 3%-5% to minimize heat buildup on the LED. The duty cycle is typically calculated for 1 second of light on-off activity, as the target strobe rate is often provided in Hz or kHz.

For special high-speed imaging situations, custom driver software may be developed by our vendors to push the limits of strobe rate and duty-cycle when needed, while maintaining safe operation.

The trigger signal for the lights may come from the camera, a vision controller, or a PLC. There are two primary methods of triggering the LEDs, based on the light controller’s configuration:

1. The Strobe Output Pulse Width Follows the Trigger Input Pulse Width

2. The detection of the leading edge of the trigger signal initiates the strobe output pulse, regardless of the trigger input pulse width.

Additional information on LED Light Controllers is available on our Light Controllers page.

Not all LED lights can be overdriven or strobed. We encourage a conversation to discuss the application details.