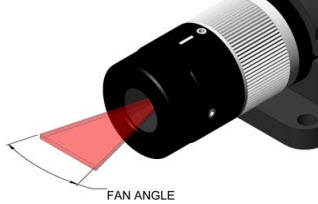

R.J. Wilson, Inc. is a dealer for Coherent, a U.S. manufacturer of precision laser line pattern generators. Coherent has been building powerful production and marking lasers for decades. Its laser line generators are used to project precise, straight laser lines with a choice of wavelength, output power, and fan angle.

The projected lines are used with a machine vision system to enable the imaging of defects, detecting presence, defining edges, highlighting gaps, mirroring a shape, or creating a datum edge when a mechanical edge is not visible in the field-of-view.

StingRay’s options include:

Coherent’s Mini has the smallest dimensions available on the market for a diode laser producing uniform intensity lines. This is a reduction in size, not in capabilities. It is designed for years of reliable operation in systems where size and weight are a limitation. Coherent’s patented line-generating optics have been integrated into the Mini to project a high-performance uniform line. The Mini is 10 mm in diameter and is ESD-protected, reverse-polarity protected, and over-temperature protected.

Mini options include: