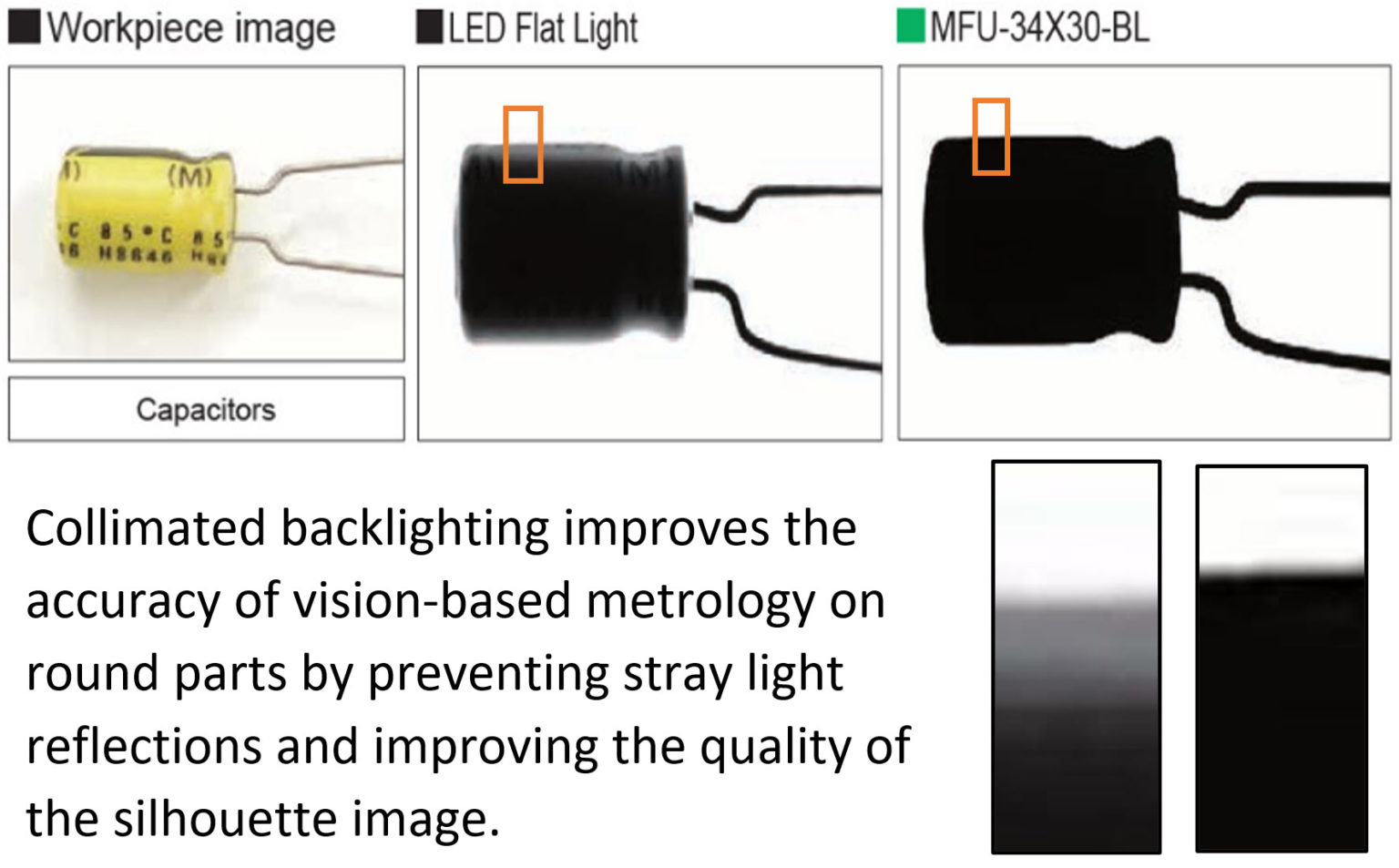

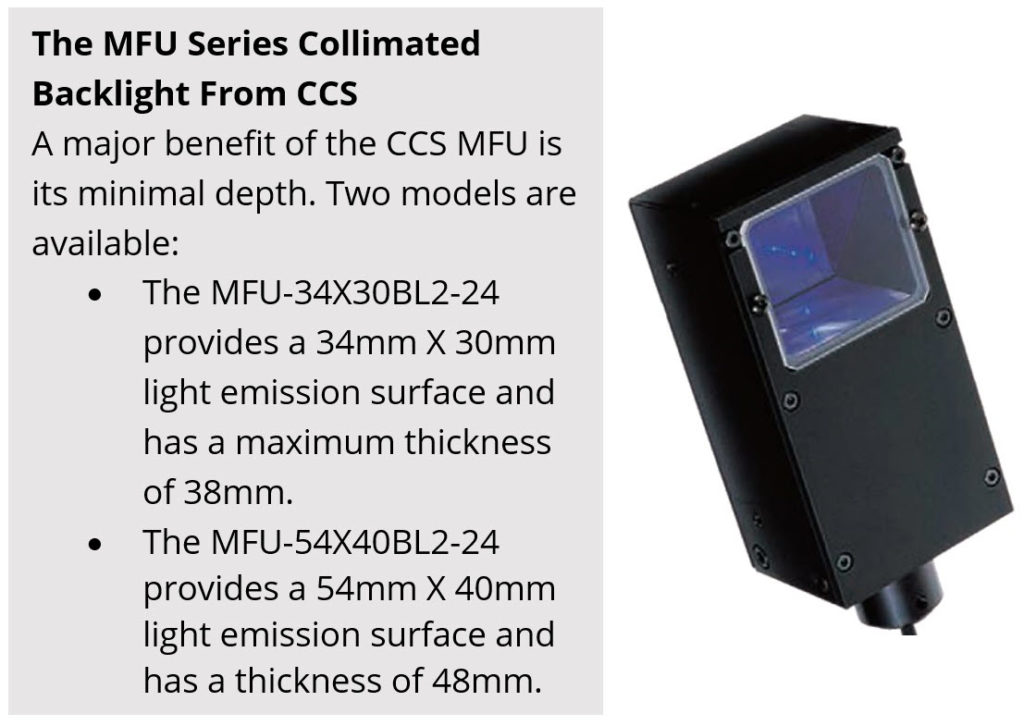

Collimated backlighting will enhance the performance of vision-based metrology systems when inspecting round parts because the light won’t “wrap around” rounded or curved edges, presenting a higher-quality silhouette image of the feature to the edge detection function of the vision software. The silhouette quality is improved whether a standard or telecentric lens is being used on the camera.

How Does the Light Wrap Around Rounded Edges?

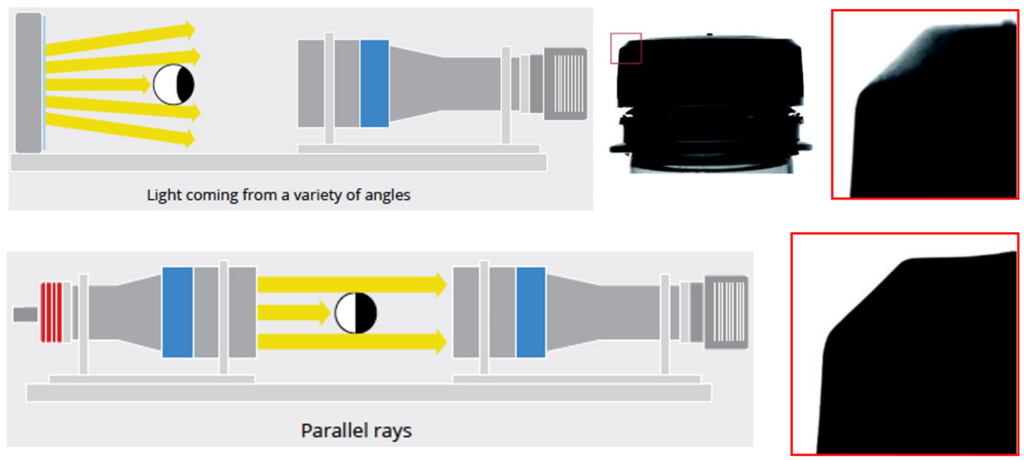

When using a standard backlight, the light rays exit the diffuse surface at all random angles, which can direct light to the sides of rounded features. Because this light is visible in the acquired image, the acquired image may contain multiple grey values within the vision tool’s region-of-interest.

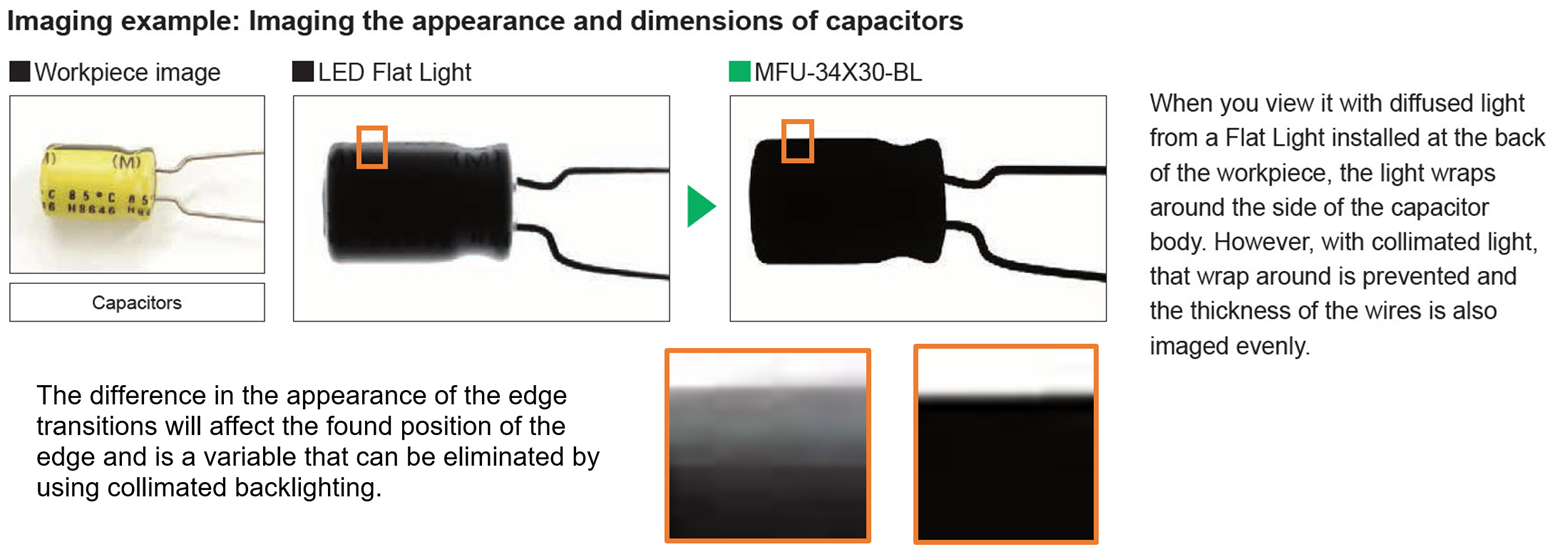

For example, an Edge tool’s consistent performance and its ability to detect the correct edge position may be affected by variations in the appearance of an edge, by the parameters set in the vision tool itself, by variations in the part’s surface finish that may reflect more or less light, and by changes in the radius of the measured part that affects how wide the greyscale transition is between the foreground and the background.

With a highly collimated light, the light rays are nearly perfectly parallel and provide a high-contrast silhouette image that supports improved metrology. Coupled with a telecentric lens, using highly collimated backlighting will provide the best possible vision-based metrology performance on rounded features and edges.

The more consistent the appearance of an edge is to the vision software, the more reliable and accurate its measurements will typically be.

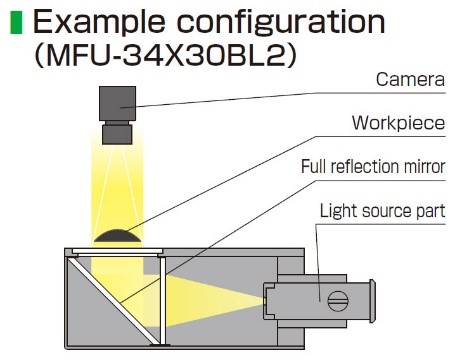

These backlights use an internal full mirror at 45° to collimate the light coming from the blue 465nm LED light source.

An application video on lens scratch detection follows and illustrates the performance difference, in this application, between standard diffused backlights and collimated backlights.

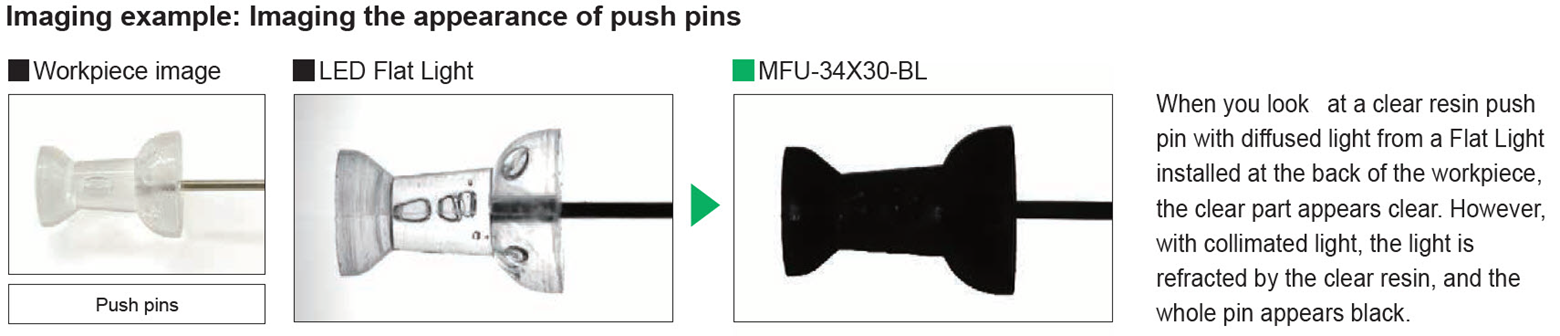

Below are additional application examples, showing 2 very different uses for the MFU collimated backlight:

A Note On the Use of Collimating Film

Collimation film is often used on standard backlights to make them more directional. This film behaves the same as privacy film used on laptop screens, where you can see your screen, but your neighbor can’t. The collimating film is providing about +/- 30° of directional control, or collimation, of the light rays. This can help minimize light diffusion on rounded edges in the appropriate applications, but collimating film will not provide highly collimated light, such as that provided by a telecentric backlight or the MFU described above.

For more information on the CCS America MFU Series Collimated Backlight, please contact R.J. Wilson, Inc. at 781-335-5500 or [email protected].