When you get down to it, the machine vision software takes in an image, whatever it may be, and applies a process to it to provide an inspection result. In 99% of cases, it’s a monochrome image, so it really doesn’t inherently matter the technique or lighting color used to acquire the image, so long as the features-of-interest appear as expected in the acquired image.

Using RGB lighting permits the user to utilize a single lighting configuration in which the wavelength of the light can be varied as required. This helps optimize the acquired image and permits storage of the RGB lighting intensities as a lighting recipe directly accessible by the machine vision system through an Ethernet connection to the light controller.

A basic imaging system consists of a camera, a lens, and a light, generating the image used by the machine vision software. Lighting is the most important aspect of the imaging system. There’s generally a “best fit” solution as far as how the light reflects off the surface, whether the solution is a back light, ring light, dome light, bar, or other configuration.

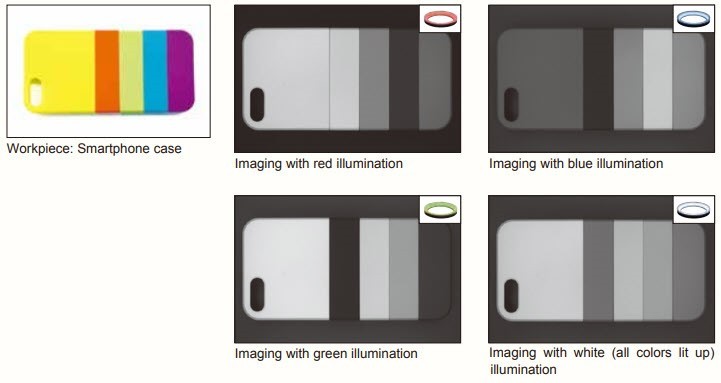

Red, Green, and Blue Light, With Every Color In Between Possible. Image courtesy of Smart Vision Lights

Once the best lighting technique is developed, the lighting wavelength is often used to create additional differentiation between features in the acquired image that could be termed “good” and “bad”. This often enables the machine vision software to more reliably determine a “Pass” and “Fail” status from the processed image.

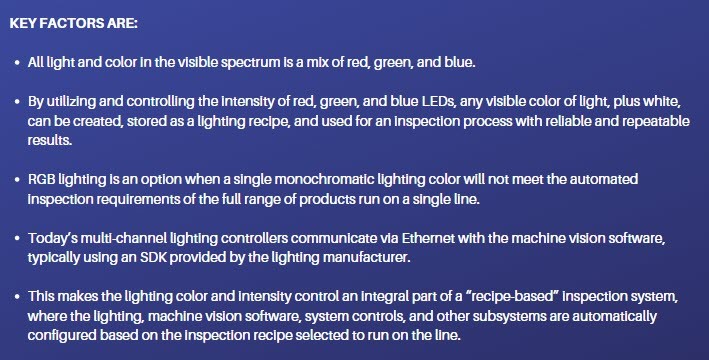

Various materials and surface colors reflect light differently when exposed to lighting of various wavelengths, seen below:

Image courtesy of CCS America

Remember the color wheel. A lighting color opposite the item color will darken the item. A lighting color close to the item color will lighten the item.

By being able to vary the lighting wavelength, the lighting color can be optimized for a variety of part configurations and inspection recipes.

To discuss your opportunity to incorporate RGB lighting, please contact R.J. Wilson, Inc. at 781-335-5500 or contact us at [email protected].