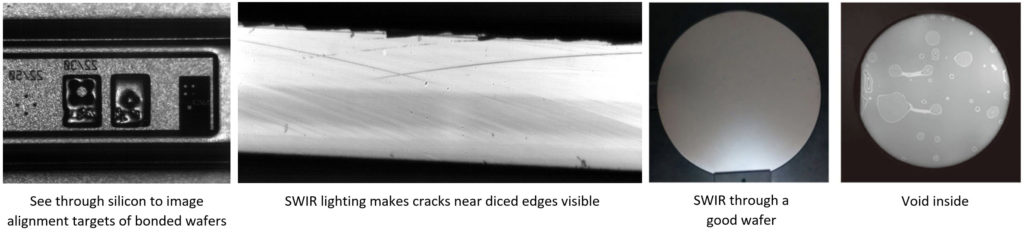

When imaging in SWIR, a greyscale image is created by the camera, much like with a visible light image. SWIR lighting, in general, is reflected or absorbed by the object being inspected, as with visible lighting. The SWIR wavelength used has a unique effect on many materials, bringing out features not detectable with visible light.

For example, SWIR lighting will pass through polished silicon wafers, making the silicon appear nearly invisible. Metal depositions on the wafer still show up in the mages, making it possible to inspect the alignment accuracy of bonded wafer targets. Features such as voids and cracks near the edges of diced wafers alter the path of the SWIR lighting as it passes through the silicon, making these features visible.

When viewing liquids, the amount of SWIR lighting absorbed or reflected is dependent on the chemical composition of the material, as seen in the image above differentiating between clear liquids.

It is often difficult to image adhesives and sealant materials when they are clear and dispensed upon a surface that may not provide sufficient contrast to make the material detectable in the acquired image. SWIR imaging and lighting may make these materials appear more prominent and detectable than when imaged with visible light, depending on their chemical makeup and how they interact with the SWIR lights.

Another benefit of SWIR lighting is that it can pass through plastic and paper packaging, making it possible to inspect liquid levels, detect content breakage, and to actually image and inspect the contents after the packaging process. This can provide enhanced final inspection of goods that may be contained in a sealed package, including medical products, food products, and pharmaceuticals.

Examples of Imaging Through Plastic Packaging

SWIR lighting will not pass through metal or metallized films or foils. For an overview of SWIR lighting, please download this document from Smart Vision Lights.

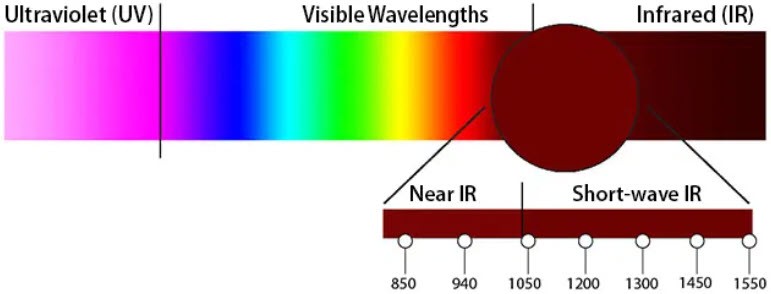

SWIR lighting is available in numerous wavelengths and, as mentioned, the choice of the wavelength is application dependent. A proper evaluation of your sample is required to determine the optimum wavelength of infrared light to use with a SWIR camera.

Typical NIR & SWIR Lighting Wavelengths

Backlighting

SWIR backlights are used for both transmissive and silhouette applications. Optical diffusers are used to ensure a smooth, even-intensity background. SWIR backlighting is available in the primary SWIR wavelengths noted above and in sizes up to 24” X 24”.

SWIR Backlights Up To 24” X 24”

Direct Illumination

SWIR front-lighting is available in many form factors, including linear lights, ring lights, and spotlights. Focused line lights are available for SWIR line-scan imaging.

SWIR Direct Lighting is Available in a Range of Form Factors

Diffuse Illumination

Diffuse dome lights are available in SWIR wavelengths. Depending on the material and its interaction with various wavelengths of SWIR light, diffuse lighting is an option to minimize glare when required. The optical grade reflector coating in the domes returns 99.9% of light for optimum diffused output.

Diffuse linear lights may be used when a larger area needs to be evenly illuminated with SWIR lighting. The Lumiform diffuser used in the Metaphase Exolights provides around 120° of uniform coverage in lengths up to 52”.

SWIR Diffuse Dome Lights & Linear Lights

High-Power SWIR Pattern Projectors and Spot Lights from Effilux

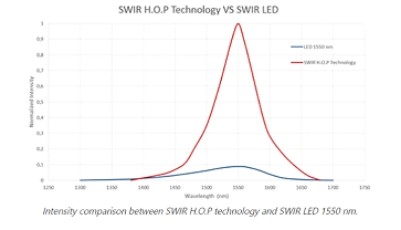

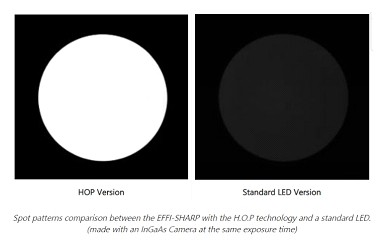

EFFILUX has developed an innovative LED SWIR source with SWIR H.O.P. (High Optical Power) Technology. H.O.P. technology is based on a proprietary material that emits SWIR light and is designed to deliver high output power.

The SWIR H.O.P. technology retains all the advantages of LEDs, compared to halogen or laser sources, but with huge improvements in power and the flexibility to create both highly-focused SWIR beams, as well as large-area uniform SWIR illumination. In fact, one “chip” of the H.O.P. technology emits a luminous flux comparable to a 50W halogen source.

The first Effilux product with H.O.P. technology is the 1,550nm pattern projector shown below. Heat-dispersion fins help keep the unit cool. When not using a reticle, this is a powerful SWIR spotlight and uses a C-mount lens to focus and direct the light.

A SWIR camera must be used to image in the 900nm to 1,700nm wavelength range. For information on SWIR Cameras, please visit the R.J. Wilson, Inc. SWIR Camera page.

To discuss the types of objects being inspected and your inspection goals, please contact R.J. Wilson, Inc. to configure a complete SWIR solution, including a SWIR camera, SWIR-coated optics, and SWIR lighting in one of many available wavelengths.

Effilux H.O.P. Technology Has its Spectral Output Peak at

the Wavelength Most Used to Detect Water

SWIR Direct Light is Available in Many Form Factors, Including for Line Scan Imaging